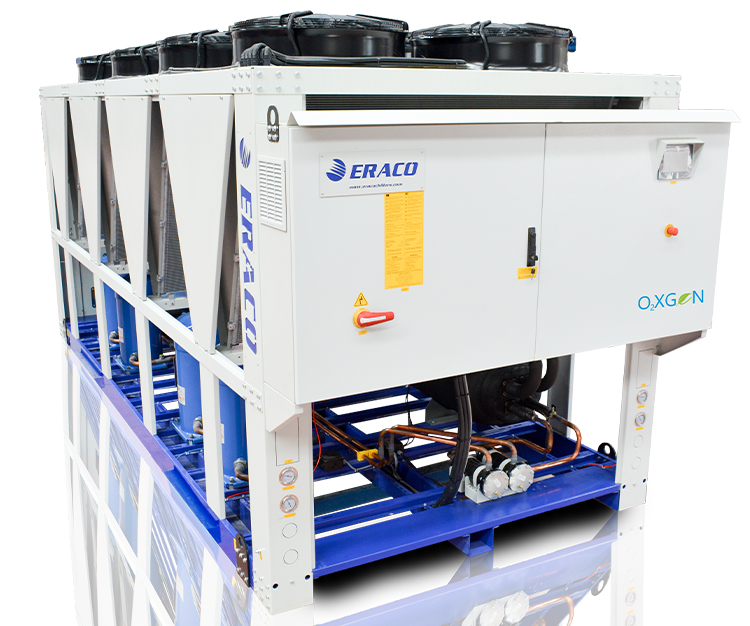

KSI Mold Conditioner

Stable temperature is of great importance in plastic mold systems that require high precision, especially operating at high temperatures. KSI series water cooled mold conditioners are used in order to meet the precise temperature requirement. In products where sufficient sensitivity is not ensured during production; adverse consequences such as surface roughness and air bubbles can be observed. Plastic should be hot enough to fill the mold during injection, and cold enough to solidify and come out of the mold after injection. During these stages, KSI series mold conditioners control the heating and cooling equipment thanks to the automatic valve groups on it, and automatically realize the capacity needed by the user.